deployable exhibition space

arch564- advanced materials structures, fall 2019prof. harry giles

ANSYS

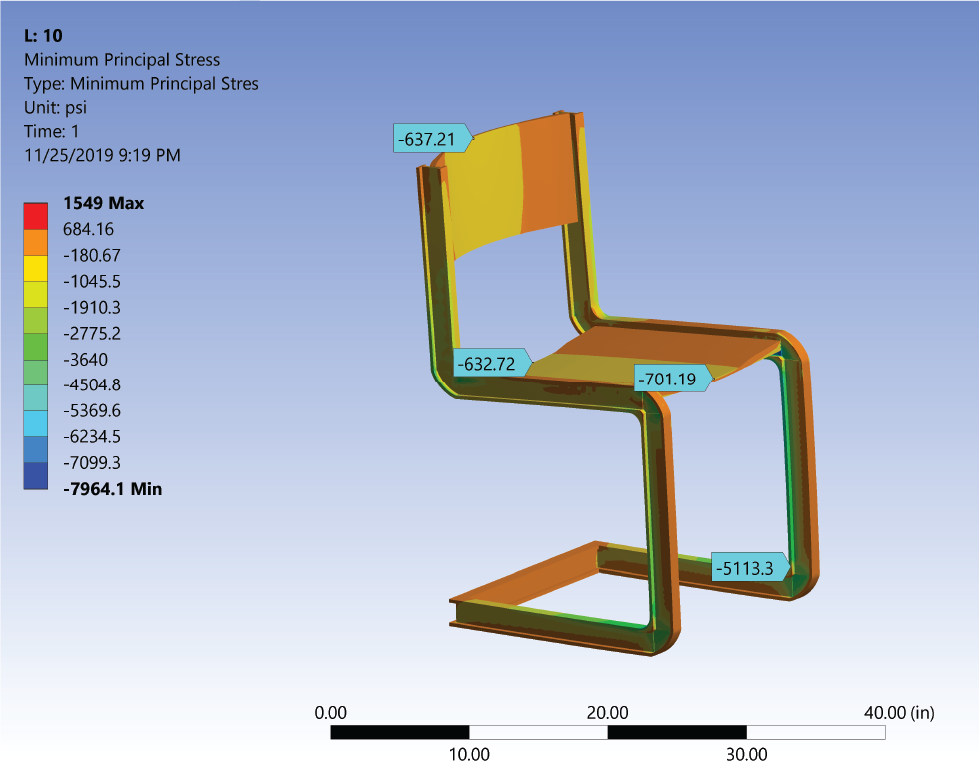

i began by taking into account that the back plywood plate failed in tension on the base model(0), but that the aluminum frame was working well. i wanted to know whether decreasing the cross section of the aluminum frame to a hollow tube(1) would affect that, and it did—the plywood tension decreased in that run, but it was still over the limit1. i expected that the plywood would fail in tension here, but that the aluminum section would not. the next step i took was increasing the thickness of the back plate to 1/2"(2). though the tension value was still quite high, as i inspected the different portions of the assembly, i found that increasing the back to 1/2" decreased stresses by about 10x. so, my next step was to increase the section of the seat. since i had also noticed that the stresses varied in the back, i also designed the profile of the back plate to respond to them—the plate is thicker at the edges than the middle(3). these two changes allowed chair number 3 to pass, with a weight of 25.74 lbs.

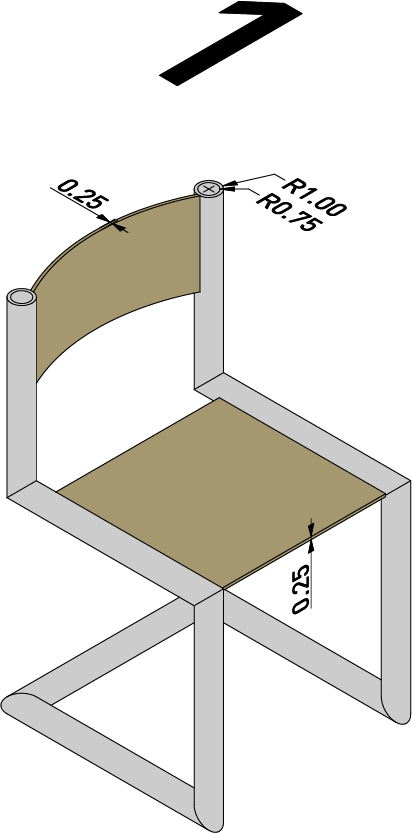

my next step was to try and reduce the weight. to do this, i tested various profile shapes. my first step was a 1” x 1” solid square section(4)2. this failed in deflection, and was the only one that did so. for the next run, i increased the cross section, but hollowed it out(5). though this passed, it was about a pound heavier than the circular version. i next wanted to see if i could reduce some local stresses i found in chair number 5, so i filleted that chair and ran it again(6). stresses dropped a bit for compression in the aluminum, so that was a success.

i also knew that i wanted to optimize the other plywood seat, so i did the same thing i did with the back and made the edges thicker, since the tension forces were limiting, and that’s where they were occurring(7). this chair also passed, but there was a bit more tension forces in the plywood, so i thought that the plywood might be reaching its limit for continued optimization.

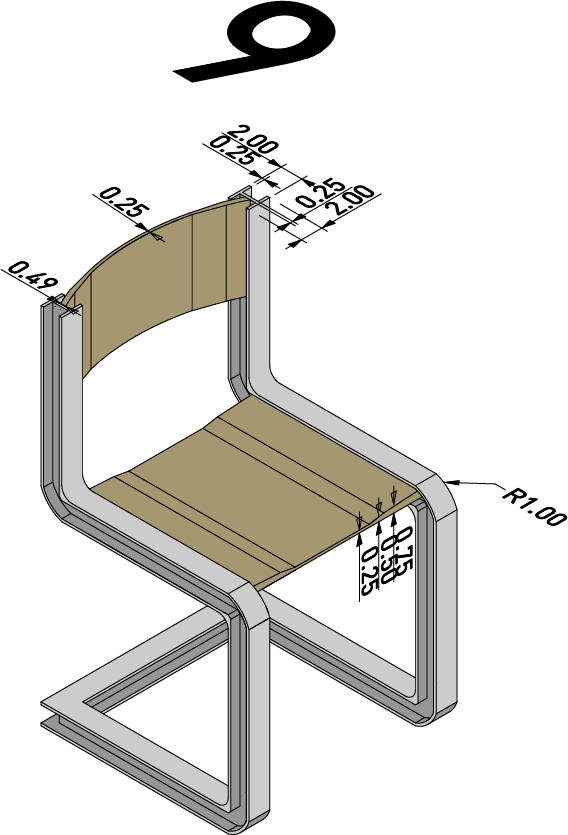

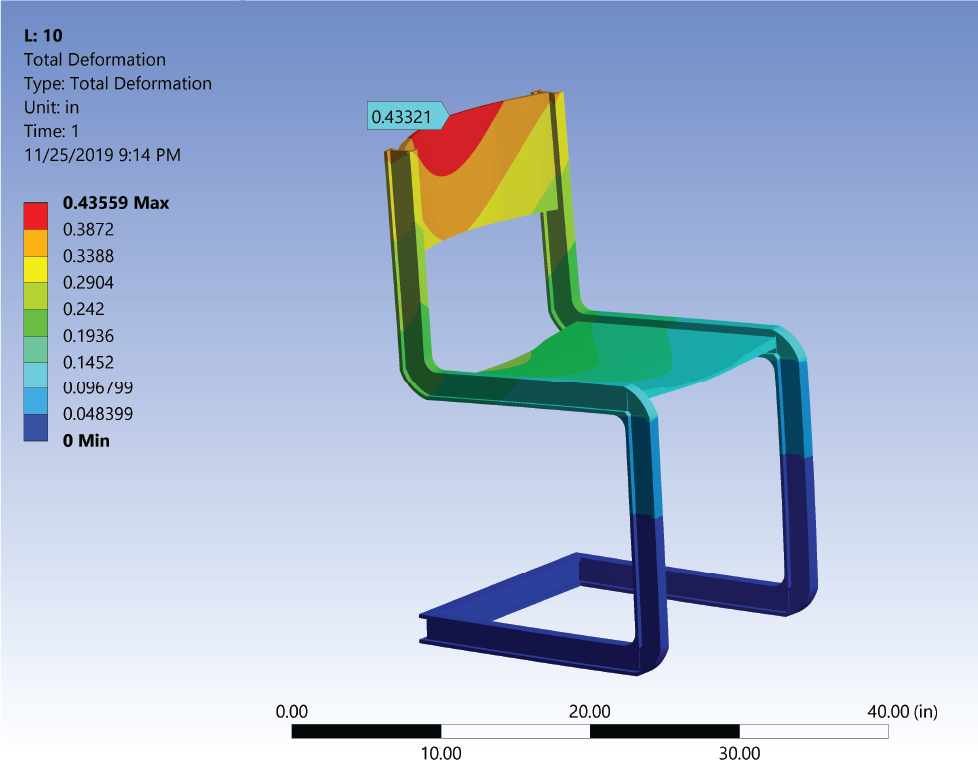

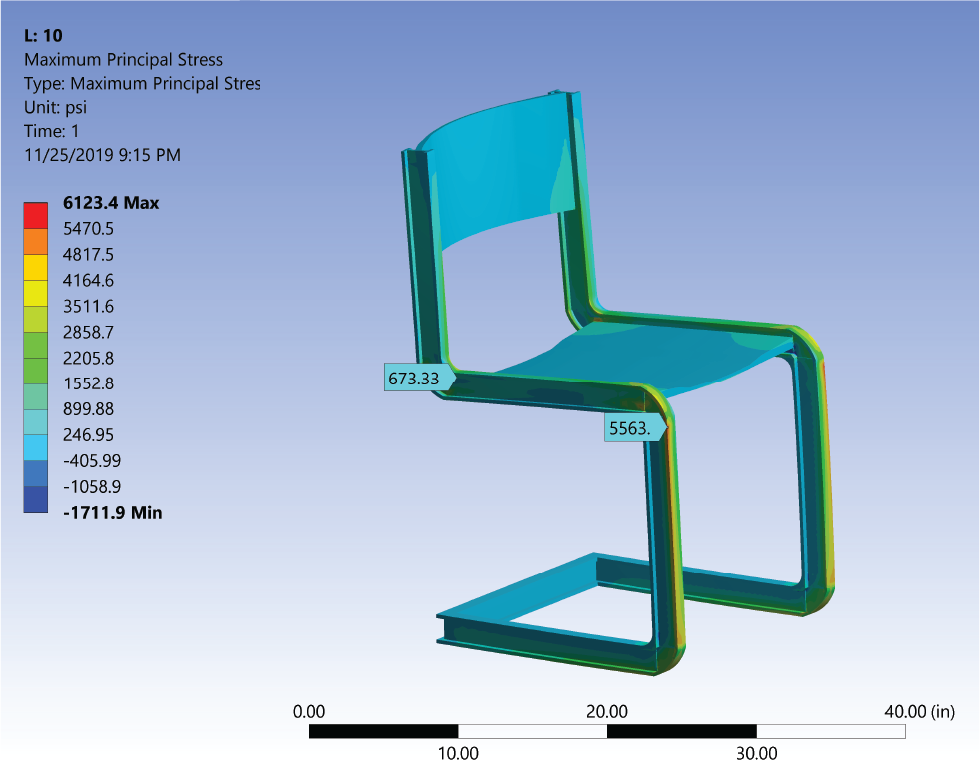

for the next run, i wanted to experiment with an i beam—having less material would cut down the weight and the flanges would reinforce the chair at the places where tension and compression were already occurring in the legs(8). this failed in tension in the plywood, so i increased the edge thickness in the seat to 3/4” to reduce the tension stresses(9)2. for the last run, i reduced the i beam’s width, keeping the height constant so as to not reduce the i-value as much(10). this final chair, with a weight of 17.47 lbs, has a cross section of a w1x2 with a flange and web thickness of 0.25”.

the two different materials, aluminum and plywood, act very differently. by changing geometric properties, an object can perform better or worse. when the frame had a higher i-value, it tended to perform better than its lower counterparts, which makes sense because an i-value tells you about geometric stiffness.

1. this trial, the probed value was more accurate than the average value. additionally, the probed value was used in developing the next trial.

2. this trial also uses the probed value, as it was more accurate than the average values.